When filtering fluids which are often circulating in your system, there tends to be magnetic debris, especially in those diesel storage tanks and cooling systems. Magnetic filters are the go-to way of removing this type of contamination in an extremely cost-effective way.

The Mag Filters are a fantastic addition to your filtration system or maintenance, not only are they able to filter out up to 99% of ferrous debris before reaching the filter cartridge, but this process alone will also increase the overall lifespan of your cartridges.

The MIcro Mags can be easily attached to your pre-existing filtration systems or even directly onto your machinery.

Standard Magnetic Filter Systems

The revolutionary MicroMag Magnetic Filter System's cutting-edge design allows users to effectively eliminate substantial quantities of ferrous contamination from systems, reservoirs, or any other application which is susceptible to magnetic filtration. Even the minute particles can be swiftly extracted from fluids. This comprehensive process serves as a safeguard against any abrasive component wear, the proliferation of bugs and bacteria development, ultimately resulting in a significantly prolonged fluid lifespan.

| Size | Flow Rate | Contamination Capacity | Max Pressure | Connection |

|---|---|---|---|---|

| 5" | 70 LPM | 1KG | 12 Bar | 1" BSP |

| 10" | 100 LPM | 2KG | 12 Bar | 1" BSP |

| 20" | 150 LPM | 4KG | 12 Bar | 1 1/2" BSP |

High Pressure Magnetic Filter Systems

The HP50 high-pressure magnetic filters deliver sub-micron filtration capabilities similar to the standard MicroMag filters, but with an extended operational range. These units are constructed entirely from aluminum, enabling the pump to withstand fluids operating at temperatures of up to 140°C and pressures of up to 50 BAR.

| Size | Flow Rate | Contamination Capacity | Max Pressure | Connection |

|---|---|---|---|---|

| 5" | 70 LPM | 1KG | 50 Bar | 1" BSP |

| 10" | 100 LPM | 2KG | 50 Bar | 1" BSP |

| 20" | 150 LPM | 4KG | 50 Bar | 1 1/2" BSP |

Why Choose Magnetic Filtration?

A significant amount of fluid is lost during the disposal of your traditional media filters. With magnetic filters however, contamination is removed from the filter as a semi-dry cake, meaning that virtually all the residue fluid can be recovered.

Magnet filtration is the process of separating and removing ferrous contamination from your liquids and fluids via the use of a very powerful magnet. This high intensity magnet attract magnetic contamination, leading to the ferrous debris sticking to the magnet. Clean fluid is then returned to the machine/system, preventing costly repairs, and extending the life of your equipment.

Other media based fine particle filtration can strip fluids of anti-foaming and anti-bacterial properties. Magnetic filters, on the other hand, enable sub-micron performance without affecting the properties, thereby reducing replacement cycle times.

Using the supplied cleaning tool, a fully contaminated core can be cleaned in under 30 seconds. Only metallic particles are removed from the filter and these can be easily disposed.

There are no dirty cartridges!

Removes up to 99% of ferrous debris

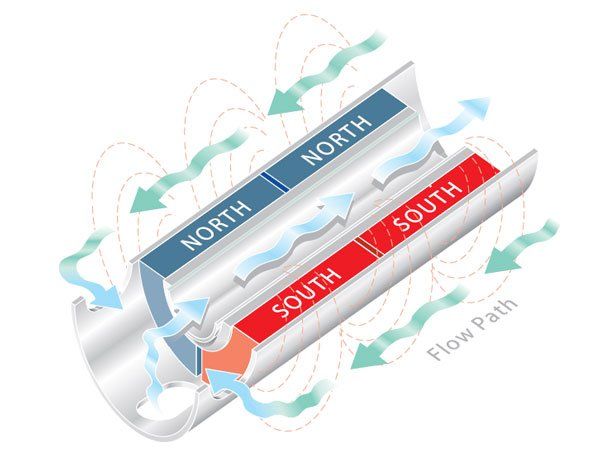

How Magnetic Filters Work

Fluids flowing around a system with a MicroMag Filter fitted will be pushed through the housing flowing up the outside of the centrally mounted Magnetic core. Here the magnetic pull will extract ferrous particles along the length before the

fluid flows down the core of the magnetic filter and returned to the system.

Secure on line payments can be made by Credit/Debit Card via SAGEPAY or PayPal

Orders and payments can also be made by telephoning our office on

+44 (0) 1246268900

Tel: +44 (0)1246268900 Email: webshop@fa-st.co.uk

Works, Office, Warehouse & Postal Address

FA-ST Filtration Analysis Services Technology Ltd,

Unit 4 Foxwood Road

Dunston Trading Estate

Chesterfield

Derbyshire

S41 9RF

United Kingdom

Main Office: +44 (0) 1246 268900

Enquiries: webshop@fa-st.co.uk

Company Registered No: 05525184

VAT Registered No: GB843062838

Copyright © 2024 FA-ST Filtration Analysis Service Technology Ltd all rights reserved