The FA-ST Oil Patch Test Kit stands out as a highly practical and cost-effective portable solution designed for swift detection and identification of contaminants in oils, diesel fuel, and coolants on the go, eliminating the need for laboratory analysis.

Key features of our oil patch test kit include:

- Instant visual analysis - Leveraging a microscope, users can visually analyse major types of system wear, including bright and black metals, fibers, silica, and more.

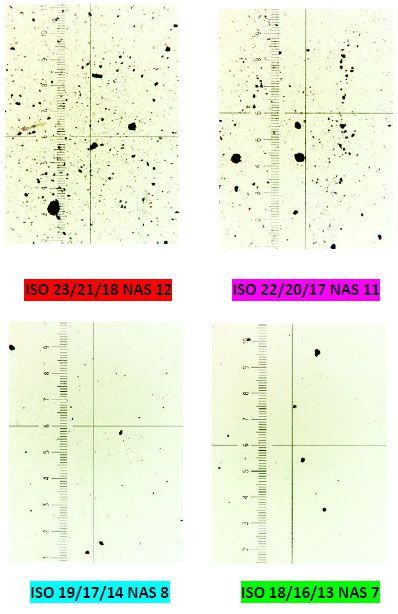

- Contamination detection - Contamination particles will become visible on the patch, enabling users to gauge an NAS Class/ISO Cleanliness rating.

- Early warning tool - This kit serves as a valuable early warning tool, offering simplicity and minimal self-training requirements.

What is Oil Patch Test Analysis?

The FA-ST Portable Patch Test Kit stands out as a crucial tool for identifying and monitoring contamination types and levels within fluid power systems. Offering a practical alternative to off-site laboratory oil analysis, this comprehensive kit facilitates immediate visual analysis using a pocket microscope and a phone camera microscope. Users can inspect major types of system wear, including bright and black metals, fibers, silica, plastics, elastomers, and more.

Ensure the integrity of your fluid power systems with this efficient on-the-go solution.

To manage costs effectively, many companies opt for in-house patch analysis testing on lubricating oils, coolants, diesel fuel, and greases, facilitating easy visual monitoring of particulate contamination.

While in-house testing may not offer the intricate analysis of a dedicated oil analysis laboratory, commercially available kits provide users with a valuable indication of the condition of their industrial fluids in real time. Commonly referred to as a 'patch test,' this process involves using MCE filters to gather and isolate debris for evaluation (colloquially known as 'patches' in the oil analysis industry). Upon completion, a patch test allows users to visually assess fluids, determining cleanliness according to ISO 4406:99 or NAS Class Cleanliness Codes. The ISO recognises the crucial connection between contaminated oils and component life, offering a cleanliness code and various standard methods, such as ISO 4406:99, as references for testers to determine acceptable particulate levels.

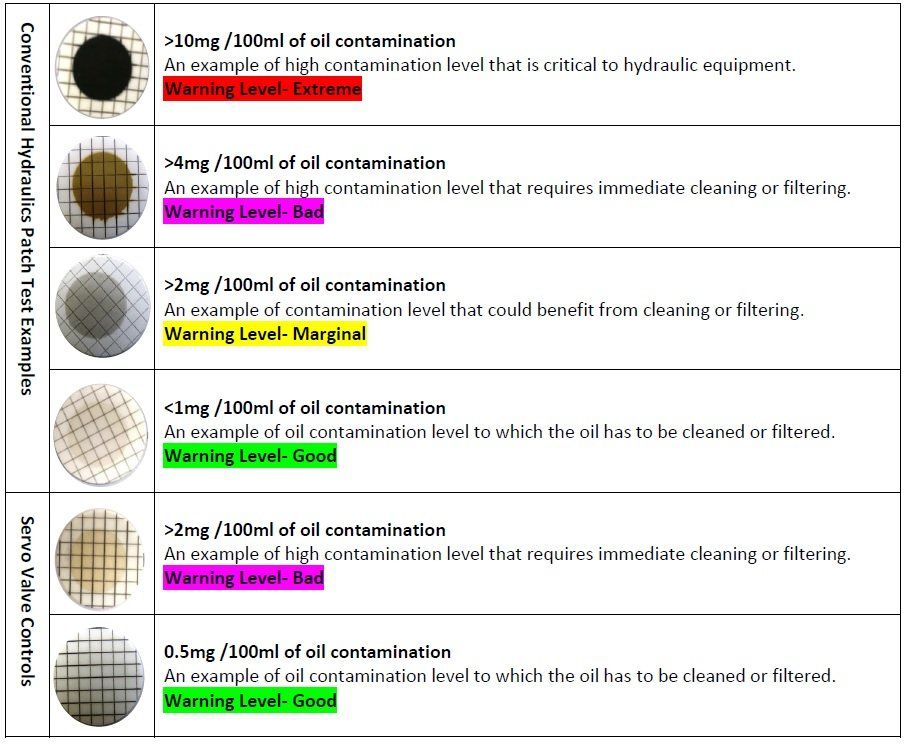

The test fluid undergoes a meticulous filtration process as it traverses a filter membrane patch via a vacuum pump. Following this, it undergoes drying and is positioned in a membrane holder, poised for visual assessment. The kit includes comparator charts to establish and approximate ISO/NAS Cleanliness Levels in fluid samples.

For the assurance of a representative sample:

- It is recommended to extract the sample from the oil or tank reservoir midpoint to avoid 'dynamic carry over' in flow lines. This prevents contaminants from lingering in the oil flow rather than entering the sample bottle.

- If sampling from a drain port is a minimess type sample point, it is advisable to let approximately half a liter of oil flow out of the sample valve before collecting the actual sample.

- Rinse the sample bottle thoroughly with the oil, repeating the process to eliminate any existing dust, ensuring a pristine sample.

- A minimum of 25ml of oil is required for the oil analysis.

Analyse your oil as soon as possible for prompt insights into its condition.

Evaluate the total contaminants in mg dirt per 100ml of oil by visually assessing discolouration and comparing it with the provided charts. It's crucial to emphasize that the evaluation focuses on the overall density of contaminants rather than specific colours.

Estimate an ISO or NAS Code by inspecting under a 50/100 x pocket microscope and comparing it with the provided charts. The grid lines on the patches, which are 100μ micron wide, serve as a reference, facilitating the identification of various contaminants.

Please take note:

Even when using a 25mm patch and collecting only 25ml of oil, express the overall contamination levels as mg contamination per 100ml. This is because the exposed area of the 25mm membrane to the sample is approximately 25% of the area exposed for a 47mm membrane, aligning with the standard laboratory test using 100ml of oil.

Our objective is to provide our customers with the fastest and easiest way to monitor fluids on their site. The patch analysis test kit is hassle-free to keep stocked, as FA-ST provides a complete range of consumables within the kit. Whether you use it, break it, or misplace it, we guarantee to keep you supplied.

Our comprehensive assortment of oil patch test refills includes:

- Vacuum Sampling Pumps

- Sample Tubing

- Sample Bottles

- Patch Refills

- Trade Wipes

- And much much more.

Visit the patch test refills section for all your supply needs.

*** Please Note FA-ST DO NOT supply petroleum ether with this kit ***

The FA-ST Oil Patch Testing Kit is the most cost effective carry case kit on the market under £500 and does exactly the same as kits costing anything between £1,000 and £3,000 for identifying and monitoring the types and levels of contamination in fluid power systems.

Secure on line payments can be made by Credit/Debit Card via SAGEPAY or PayPal

Orders and payments can also be made by telephoning our office on

+44 (0) 1246268900

Tel: +44 (0)1246268900 Email: webshop@fa-st.co.uk

Works, Office, Warehouse & Postal Address

FA-ST Filtration Analysis Services Technology Ltd,

Unit 4 Foxwood Road

Dunston Trading Estate

Chesterfield

Derbyshire

S41 9RF

United Kingdom

Main Office: +44 (0) 1246 268900

Enquiries: webshop@fa-st.co.uk

Company Registered No: 05525184

VAT Registered No: GB843062838

Copyright © 2024 FA-ST Filtration Analysis Service Technology Ltd all rights reserved