Oil Testing

Ensuring that your equipment and systems operate at peak efficiency involves eco-friendly and cost-effective monitoring of your fluids. This not only confirms that the oil provides the necessary protection and lubrication but also helps detect contamination and wear particles that may impact performance and sustainability.

We offer comprehensive oil testing solutions, including fluid analysis through our independent laboratory, along with a range of on-site testing products to minimise waste and transport emissions.

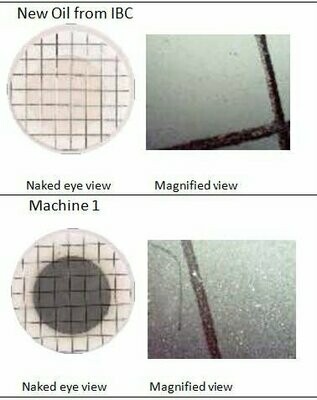

Our services provide valuable insights into your fluids through wear particle analysis, contamination level assessments, and chemical composition analysis of fluids like lubrication oils, diesel fuel, coolants, and greases. With both laboratory analysis and on-site tools such as our Oil Patch Test Kit, Kolor Kut Pastes, and Diesel Bug Testing & Treatment Kits, we empower you to take proactive, environmentally responsible measures that extend fluid life and reduce environmental impact.